Advantage in using SHS Cleats

What is the main advantage of using shs cleats?

A Smarter Way to Build: The Advantages of SHS Cleats from www.shscleats.com.au

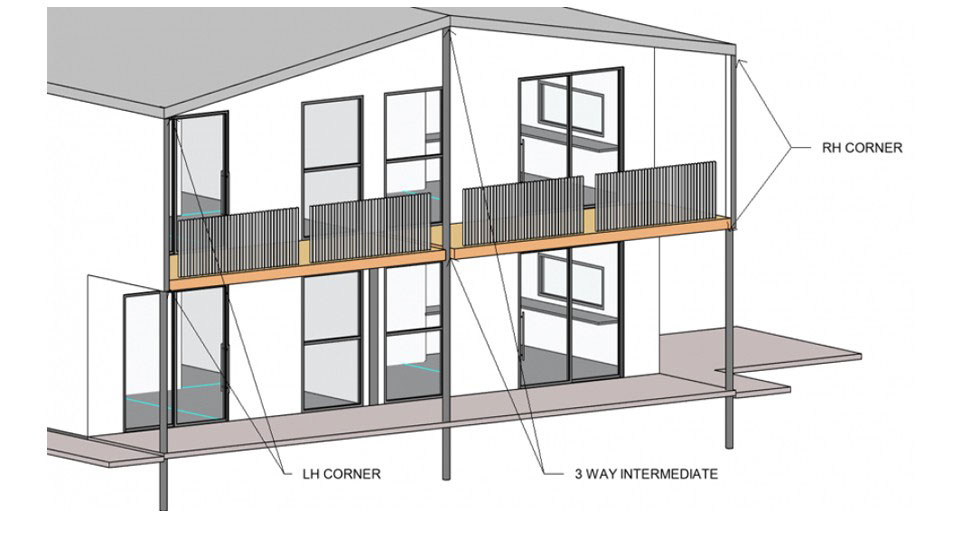

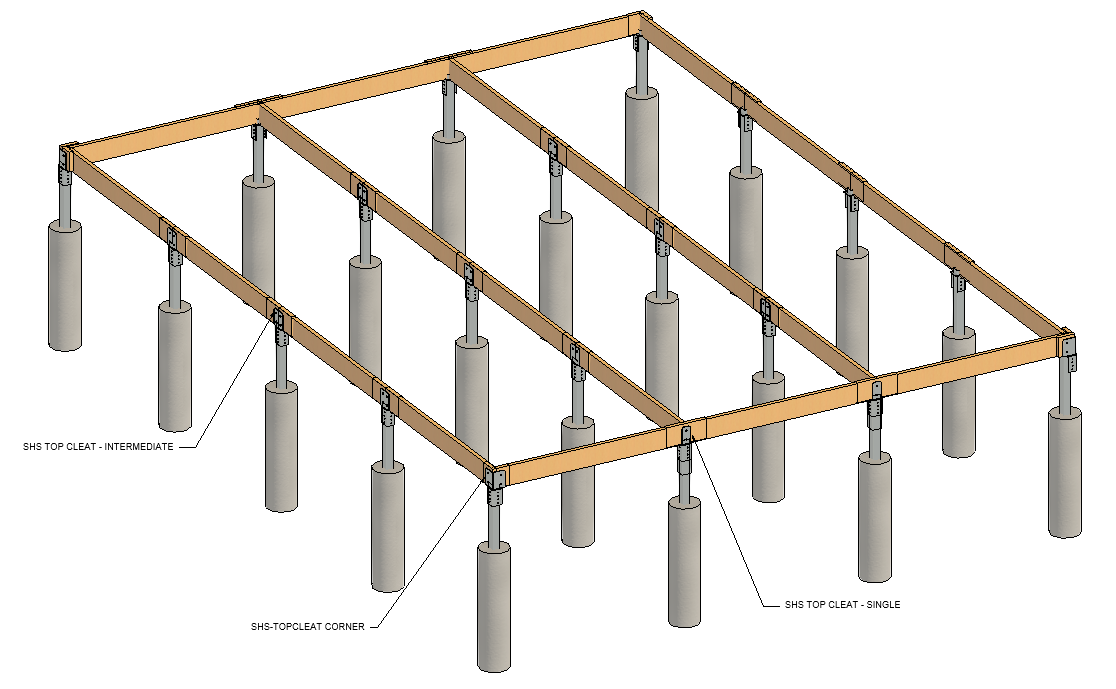

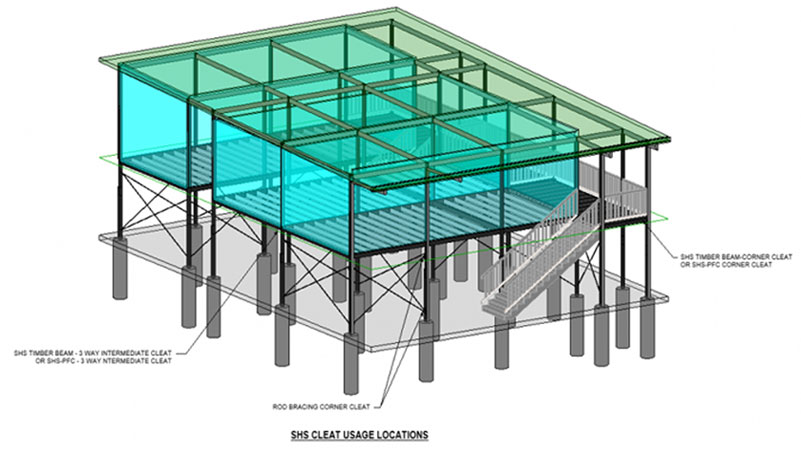

In the world of construction, time is money — and precision is everything. That’s why builders across Australia are turning to a smarter, more flexible solution for assembling SHS posts, cleats, and baseplates: SHS cleats from www.shscleats.com.au.

Traditional Method vs. SHS Cleats: What's the Difference?

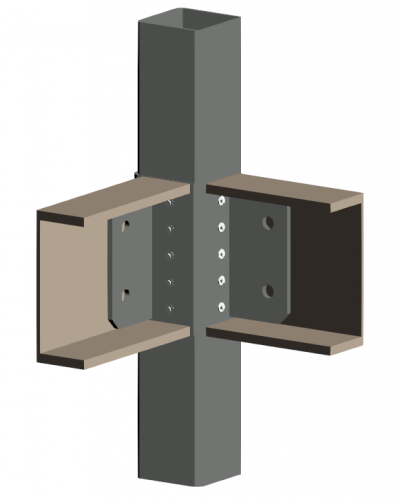

In conventional construction practices, cleats and baseplates are typically welded to SHS posts in a factory, forming long, rigid assemblies that are then transported to the site. These welded SHS posts — often up to 4 metres long — are heavy, cumbersome, and difficult to handle. Once on site, positioning them accurately both horizontally and vertically can become a logistical headache, especially when minor adjustments are needed due to changes in beam levels or site conditions.

This is where SHS cleats shine.

The SHS Cleats Advantage

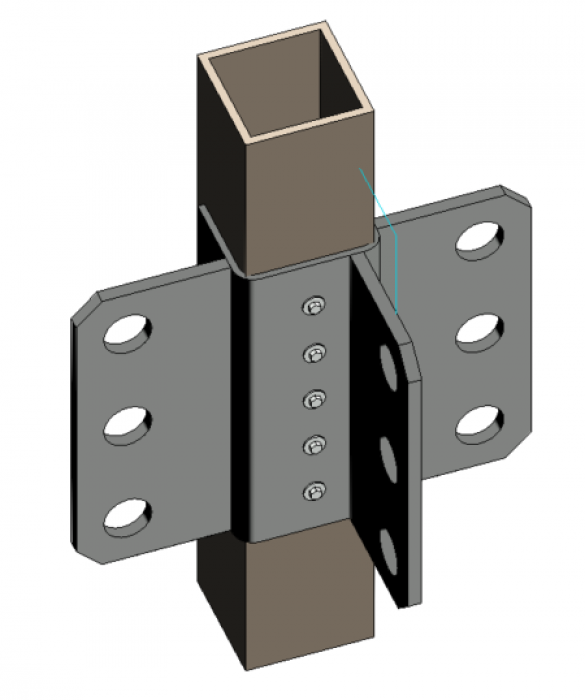

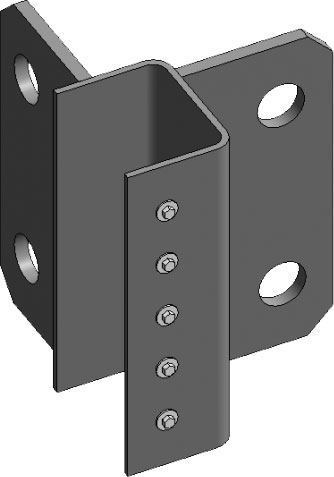

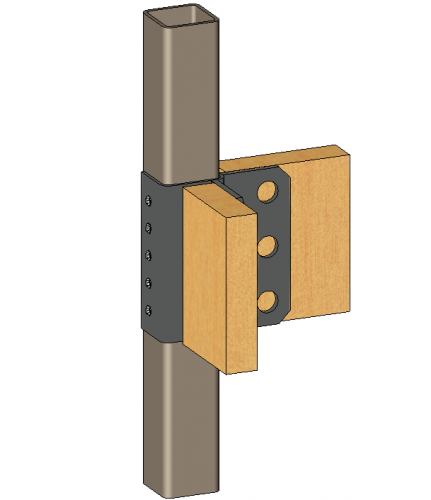

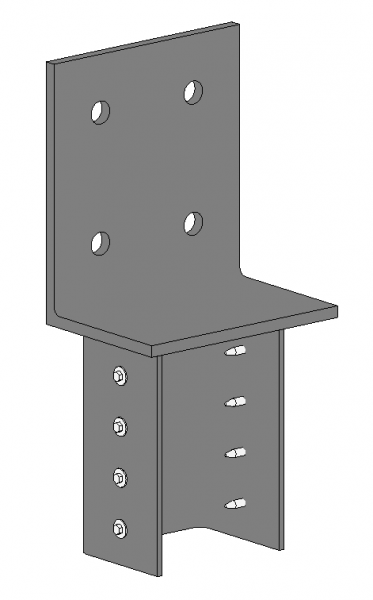

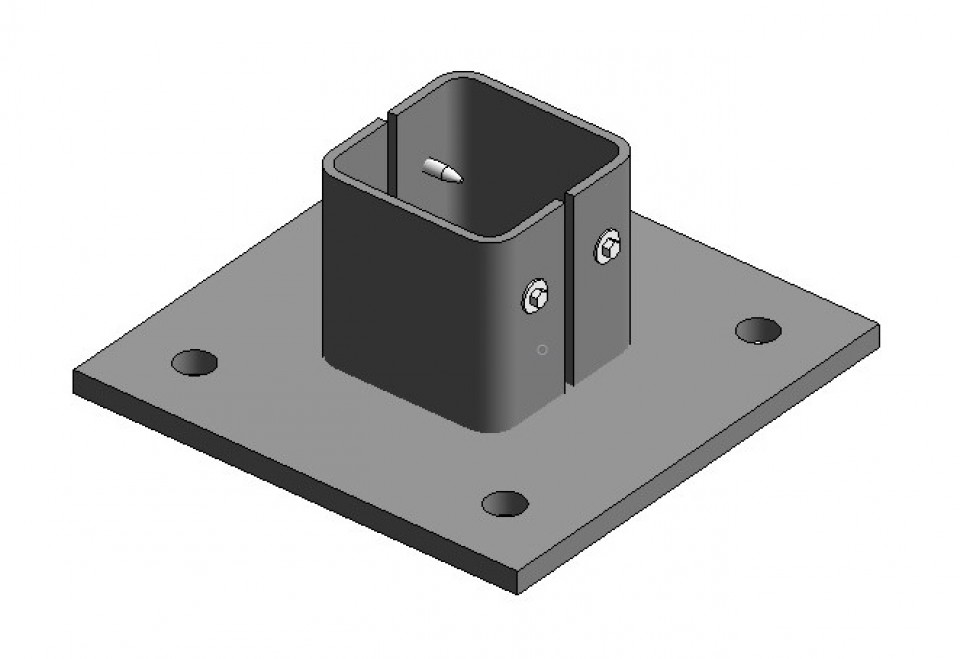

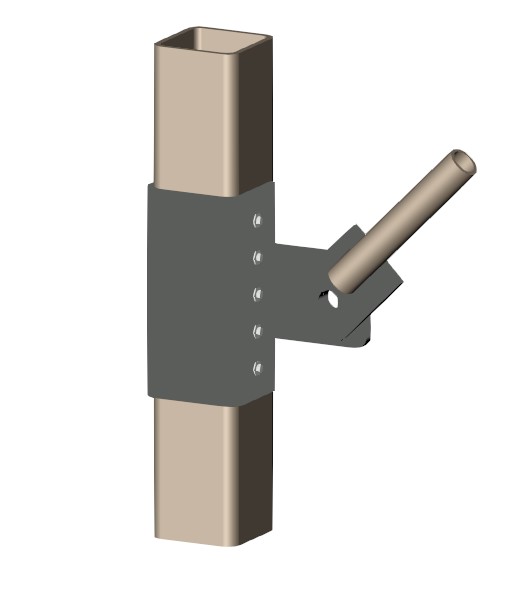

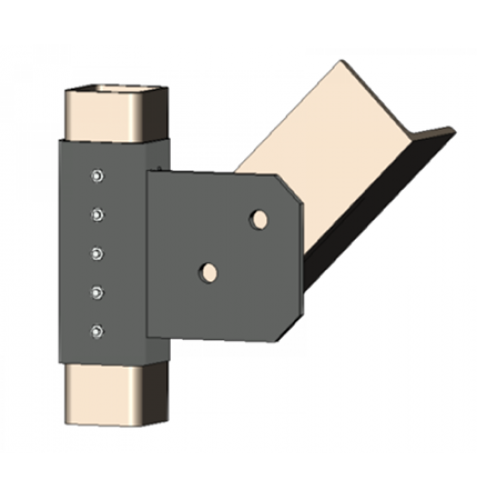

At SHS Cleats, we’ve designed a system that gives builders greater flexibility, control, and efficiency. Instead of pre-welding everything in the factory, our system allows builders to assemble the SHS posts, cleats, and baseplates directly on site — no welding required.

Here's how our SHS cleats make the difference:

Simple On-Site Assembly

SHS cleats slide directly onto the SHS posts and can be securely fastened in place. No special tools or welding equipment needed — just straightforward mechanical assembly.

Adjustable Beam Levels

One of the biggest challenges on site is dealing with unexpected level changes. Our SHS cleats can be easily adjusted up or down the post, allowing for fast and accurate alignment to suit real-time beam height requirements.

Greater Accuracy

Because adjustments can be made on site, the builder has complete control over post and cleat positioning. This ensures a more precise fit for beams and structures, reducing rework and increasing build quality.

Time & Cost Savings

Avoiding factory welding means less lead time and lower transport costs (no more 4m welded assemblies). It also means fewer delays and a faster overall build time — a clear win for builders and developers alike.

Builder Empowerment

The control is now in the hands of the builder. You no longer have to rely on factory-fixed cleat positions. If something needs to change, you slide the cleat, secure it, and move on.

A Practical Solution for Real-World Challenges

SHS cleats from www.shscleats.com.au provide a practical, flexible alternative to traditional welded systems. They’re ideal for projects where precision, adaptability, and speed are essential — and they make life significantly easier for builders working in unpredictable site conditions.

Whether you're managing a small structural installation or a large-scale commercial build, our SHS cleats offer the speed, accuracy, and control you need to get the job done right — the first time.

![]() CATEGORIES

CATEGORIES